Why 40oz Tumbler is the New Status Symbol in 2025-2026?

Gone are the days when status was defined by the luxury watch on your wrist, the sports car keys on the table, or the designer

Not finding a perfect match? Contact us – this catalog is just a glimpse.

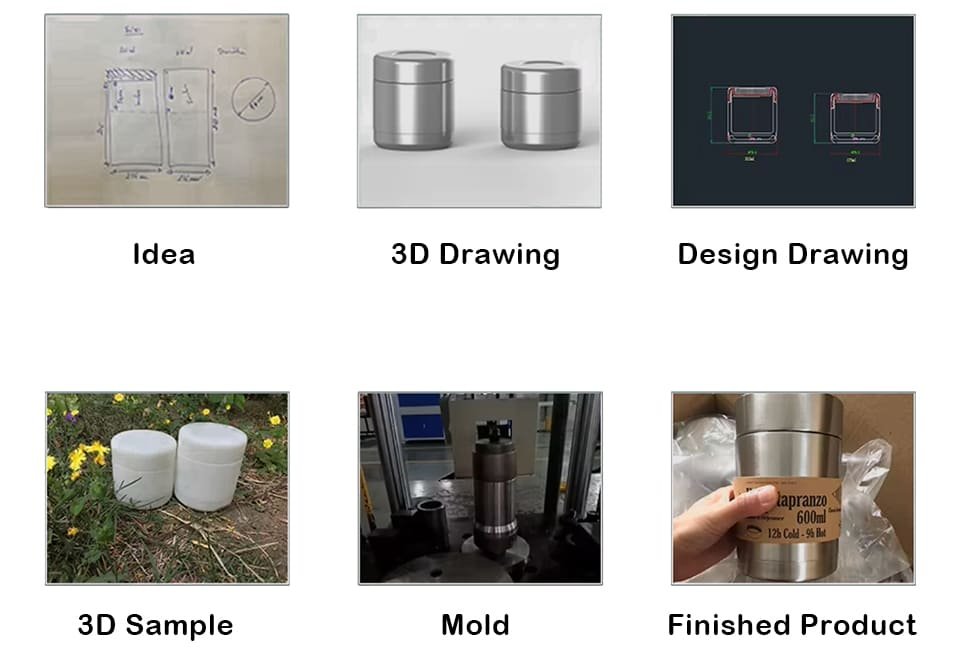

As a benchmark in the insulated drinkware industry for over 15 years, Ingfan stands as one of China’s largest manufacturers. We possess end-to-end capabilities, managing the entire product development journey from concept design and prototyping to rigorous testing and mass production.

We utilize premium materials like stainless steel and food-grade plastics, with every product meeting the highest quality control standards. Our tailored OEM/ODM solutions are designed to fit your specific needs, backed by our managed global logistics for seamless delivery.

Committed to innovation and sustainability, we collaborate closely with you to transform your ideas into market-ready, exceptional products.

Contact us at sales@ingfan.com. We respond within 24 hours.

Your project, our expertise. Let’s create together.

+86-16601250586

sales@ingfan.com

+86-16601250586

How to customize

FAQ

A: Placing an order is simple. Just send us the model number, a product picture, or even your own design idea. We will then discuss the details with you to confirm the order.

Once the order is confirmed, we will issue a proforma invoice and a contract for your review.

Regarding Payment:

For orders of 3,000 units or more, a 30% deposit is required to initiate production, with the remaining 70% balance due before shipment.

Our Production Lead Times:

We offer different production schedules to meet your needs:

A: Our MOQ starts at 300-500 pieces for stock items with simple logo customization, helping you minimize inventory risk. For full customization involving colors, designs, or packaging, the MOQ is 3,000 units.

A: Yes! Customization is our specialty.

Our factory is built for ODM / OEM. Bring us your idea, and we can help customize everything from the overall style, color, and finish to the design, logo, packaging, and even accessories.

A: Absolutely. We are more than willing to sign your confidentiality agreement and take it very seriously. We’ve signed NDAs with numerous clients because we deeply respect their privacy and proprietary information. Safeguarding your designs and ideas is not just a policy—it’s a principle we hold sacrosanct.

A: We offer a comprehensive range of stainless steel drinkware and related products. Our main categories include:

This is just a glimpse. We welcome the opportunity to discuss your specific needs and provide our full catalog. We have more than 1600types and Introduce many new models every year.

A: Yes, we strongly encourage sample orders, which is a standard practice for brands and wholesalers to verify quality. We offer two sample types with different lead times:

A: Yes! We accommodate small batch orders.

For our existing stock models, the Minimum Order Quantity (MOQ) starts from 300-500 pieces. For these small batches, we offer simple logo customization, including laser etching / silk screen printing or single-color / multi-color UV printing. We are here to help you start with flexibility.

A: That’s an excellent question. Even with identical specifications, several key factors contribute to price variations. It’s often a reflection of what goes beyond the basic materials.

In short, the lowest price might mean corners have been cut in areas you cannot easily see. We choose to invest in consistent quality and reliable performance, ensuring your brand receives the best value and minimizes product risks.

A: While high-quality materials and precision engineering are fundamental, we believe the most critical element transcends the physical product itself: it is the mindset and responsibility of our people.

Modern machinery is essential, but it is operated and overseen by individuals. Through years of experience, we have learned that a truly excellent product is ultimately born from a culture of excellence. We invest heavily in cultivating our team’s comprehensive skills and fostering a shared commitment to not just meet, but exceed, the stringent standards demanded by international brands.

A single tumbler passes through dozens, even hundreds of processes. It is the conscientious care and pride of every employee at each step that ensures perfection. We have forged a team with an intrinsic drive for high standards. This human-centric philosophy is why the products we create earn the trust and recognition of leading global brands, giving you the confidence to sell without second thoughts about quality.

A: That’s fantastic! Creating a unique product is an exciting journey, and we’re here to guide you every step of the way. Here is our collaborative process:

This structured approach ensures that your vision is perfectly translated into a tangible, high-quality product, minimizing risks at every stage

We will reply you in 24h

Our Blogs

Gone are the days when status was defined by the luxury watch on your wrist, the sports car keys on the table, or the designer

In the global supply chain, China stands as the core hub for tumbler manufacturing, with mature production technologies capable of achieving everything from basic to

We would love to hear from you

Ingfan Drinkware